Our Social Impact

Occupational Health and Safety

Occupational Health and Safety Management System

Our HESS policies are derived from values and practices that have guided the company’s plans and decision making for decades.

We are committed to providing a safe and healthy work environment for our employees and visitors, and protecting our neighbors from offsite impact. Our company promotes continuous improvement in these areas through certified management systems that include risk assessments, hazard mitigation, defined goals and objectives, management review meetings, incident investigation and robust compliance audits. We promote our belief that health and safety is as much a line responsibility as production and quality.

We clearly communicate potential hazards associated with our products to promote their safe use.

Neo Performance Materials promotes occupational health and safety management systems at all its facilities. Eighty nine percent of Neo’s manufacturing personnel operate in a plant that carries an external ISO 45001 – Occupational Health and Safety Management System certification. This management method has been promoted by Neo management for more than a decade to drive strong performance and demonstrate our commitment by using an internationally recognized standard. Those facilities that are not yet certified have many, if not all, the ISO-45001 elements in place.

These certifications require risk assessments, review of required regulations, annual goals and objectives as well as management review meetings. At the corporate level, a similar system is in place in which an aggressive list of HESS improvement goals and objectives are developed in management review meetings. Site Managers, HESS Managers, the Executive Team, and the Board’s HESS Committee all participate in the corporate goal setting process. The Executive Team and the Board track progress quarterly.

This process includes a robust HES audit system that uses site-specific documents (System Status Reports). These documents attempt to identify key regulatory requirements, applicable corporate standards, and site-specific risk reduction requirements and consolidate them into one document. These reports were developed by Corporate Health and Safety, in conjunction with Neo professionals that work in that region, and external HES consultants. While these documents are the basis for Neo corporate audits, the intent is to have a useful document from which sites can monitor their systems internally. The document is not meant to be a periodic checkup, but a continuous review of our prevention systems.

FACILITY

Tianjin, China

Zibo, China

Jiangyin, China

Chuzhou, China

Korat, Thailand

Sillamäe, Estonia

Sagard, Genrmany

Hyeongok, South Korea

Peterborough, Canada

Quapaw, Oklahoma

STANDARD

ISO-45001 Occupational Health and Safety Management

ISO-45001 Occupational Health and Safety Management

ISO-45001 Occupational Health and Safety Management

Recent acquisition; in process of on-boarding Neo’s standards

ISO-45001 Occupational Health and Safety Management

ISO-45001 Occupational Healthand Safety Management

<25 people

ISO-45001 Occupational Healthand Safety Management

Most ISO-45001 elements in place <25 people

ISO-45001 Occupational Health and Safety Management <25 people

Hazard Identification, Risk Assessment, and Incident Investigation

Because hazard identification and risk assessment are basic to health and safety systems, Neo includes these components in their internal HESS standards. Whether the standard is on the control of hazardous energies, hot work, furnace safety, contractor safety, or industrial hygiene, they all start with an identification and assessment of the hazards followed by the implementation of mitigation steps. As part of the ISO-45001 process, personnel are trained in the “Hierarchy of Controls” to achieve optimal risk reduction. Compliance with internal standards is part of the corporate HESS audits.

Over the past few years, Neo HESS has been developing and disseminating training modules on an internally developed methodology named the Pre-Task Risk Assessment process. This method teaches personnel to first spot the energies available in each job step, followed by an assessment of the risk the energy may pose, then priority-based methods to reduce the risk.

Neo Performance Materials, HESS standard 6.1 is titled Accident/Incident and Non-Conformity Investigations, defines the minimum requirements for company facilities. Each site must have a written investigation procedure that covers near miss incidents, employee and visitor accidents, process incidents, security incidents, and environmental incidents. A root cause investigation methodology is also required. In support of this requirement, the corporation teaches a four-hour, participative course titled, “Causal Root Investigation.” This is a team centered investigation method that promotes open communication. Part of this training is the Hierarchy of Controls as well as the identification of management system deficiencies.

In support of a rigorous investigation and reporting system, the corporation sets annual goals for each plant requiring a minimum number of near miss incidents to be found and investigated. The sites routinely meet their annual goals.

Occupational Health Services

Neo’s internal, Industrial Hygiene standard, element 7.1.1 states,” A systematic exposurehazard assessment will be conducted by a qualified professional. As of the end of 2021, this effort has been completed for all sites, including the new facility. This standard goes on to require a priority-based air sampling strategy. Corporate HESS has been involved in defining sampling equipment, sampling methods and analytical laboratories. When concerns are noted, corrective actions are put into place. The corporate standard 7.1.8 states that Engineer controls will be implemented to control exposures whenever feasible.

Occupational Health Services

Neo’s internal, Industrial Hygiene standard, element 7.1.1 states,” A systematic exposurehazard assessment will be conducted by a qualified professional. As of the end of 2021, this effort has been completed for all sites, including the new facility. This standard goes on to require a priority-based air sampling strategy. Corporate HESS has been involved in defining sampling equipment, sampling methods and analytical laboratories. When concerns are noted, corrective actions are put into place. The corporate standard 7.1.8 states that Engineer controls will be implemented to control exposures whenever feasible

OHS-Related Worker Participation, Consultation, and Communication

The ISO-45001 Occupational Health and Safety Management System standard, in section 5.4 defines the acceptable standard for consultation and participation of workers. As a company that utilizes this standard, our efforts in this regard are externally audited. In those few, smaller plants that are not audited, participation is required by government requirement and promoted by the company. The details of how each site fulfils its duty to involve personnel vary slightly from site to site, as employee participation is frequently covered by location specific governmental regulations. Typically, employee participation is via a site health and safety committee. Neo supports this concept by requiring each manufacturing facility to conduct a “Management Walkthrough.” In these walkthroughs, an audit document is provided by Corporate HESS featuring a quarterly topic. In addition to top management representatives, a representative from facility operations is invited to attend.

Many of our sites have adopted visual management techniques and applied them to HESS. HESS bulletin boards or digital boards help communicate key information to operators.

Worker Training on Occupational Health and Safety

Each site has defined health and safety training requirements. These requirements must consider local regulatory training requirements, ISO-45001 training needs, training required by corporate standards, and additional training the site deems necessary. Much of that training is classroom training or hands-on.

The company is in the beginning phase of introducing customized, computer based, health and safety training in four languages. An advantage of computer-based training is that it is available twenty-four hours per day and it can be customized to include local learning objectives. Each training module is based on the Pre-Task Risk Assessment methodology, in which students are asked to spot the energy in each job step. The training sessions then go on to teach the hazards of each energy form. Presently three modules have been made on gravity, three on chemical energy, and one on biological. The videos include the feature of having various site experts involved in the training.

Prevention and Mitigation of OHS Impacts Linked to Business Relationships

Neo uses the Globally Harmonized System (GHS) for conveying potential health and safety hazards associated with their products. This means products are shipped with safety data sheets and warning labels that meet the GHS standard.

Workers Covered by OHS Management System

Eighty nine percent of Neo’s manufacturing personnel operate in a plant that carries an external ISO 45001 – Occupational Health and Safety Management System certification.

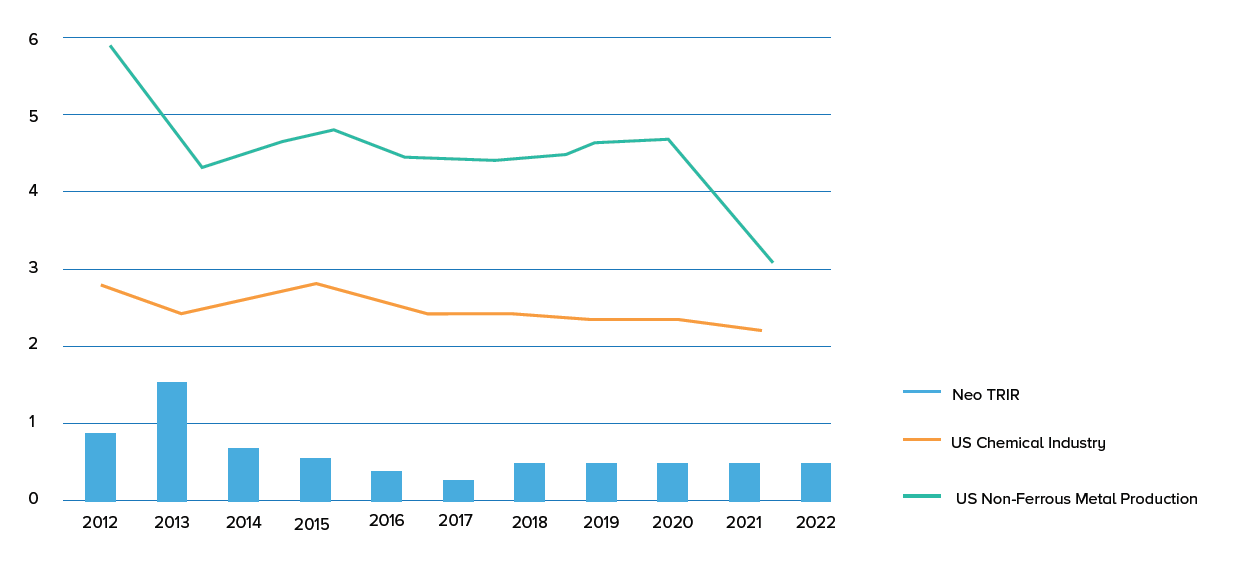

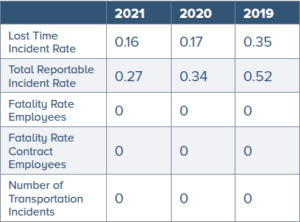

Work-Related Injuries

Work-Related Ill Health

The number of Occupational illnesses reported in 2021, 2020, and 2019 was zero.

Response to COVID-19

Corporate staff has kept its fingers on the pulse of the COVID-19 virus since the outset. This includes biweekly reports from all locations regarding preventive measures, quarantines, number of personnel vaccinated, etc.

The most important statistic is this; there have been zero COVID-19 deaths reported. The majority of NPM employees work in Asia; in 2021 there were zero COVID-19 cases in that area. There was an outbreak in the Sillamäe, Estonia region where we have a manufacturing facility. In 2021 there were 100 COVID-19 cases reported, 99 of which were from that region.

The graph below shows the outbreak and a return to control. Internal contact tracing efforts indicated that the strong majority of cases came from contacts outside of work.

To combat the spread of infection, the plants have employed mask rules, social distancing, temperature

monitoring, quarantines, training, vaccination availability at plant sites, and testing. In addition, Neo procured abundant supplies of PPE for all its employees, making an effort to prefer local manufacturers in order to support the domestic manufacturing of the communities that in which Neo’s plants operate. New protocols were developed and implemented for cleaning staff to disinfect high-touch surfaces. As of the end of 2021, 88% of NPM personnel had been vaccinated.

Most administrative personnel and colleagues that were in high-risk demographics were encouraged to work from home. For some operating facilities in areas of high case counts,

Neo implemented measures requiring employees to disclose their international travel and to quarantine post-travel before return to work. Sick leaves were encouraged, when personnel exhibited even early indications of symptoms. Subcontractor site visits were limited to the minimum level feasible.

As a result of Neo’s efforts to address the risks of COVID-19 – deploying considerable resources and very careful management – there were no plant closures in 2021.

Monthly COVID-19 Cases in Neo

No Data Found